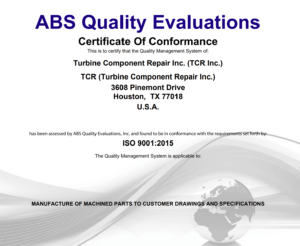

TCR is pleased to announce the successful completion of the Renewal Audit to maintain its’ ISO 9001:2015 registration. Advancements in policies, processes and procedures following the original surveillance audits, were found to fully satisfy ISO 9001:2015 standards. “Once again the TCR team exceeded expectations by successfully meeting the requirements of the ISO Quality Standards and their commitment to continual improvement.” ISO-9001 is a global quality management system designed to help organizations ensure that they meet the needs of customers while meeting statutory and regulatory requirements. The standards are published by ISO, (International Organization for Standardization).